In the dynamic world of Lean Six Sigma, monitoring process improvements is an integral component of the methodology. Lean Six Sigma seeks to eliminate waste, reduce variation, and enhance customer satisfaction. By closely tracking the performance and outcomes of your improvement projects, you can ensure that they align with your goals, identify any gaps or issues, and sustain the benefits over time. In this article, we will explore how to effectively monitor process improvements using various tools and techniques of Lean Six Sigma.

Define Metrics and Baselines

Before embarking on any process improvement journey, it’s crucial to establish the metrics that will gauge the success of your projects. These metrics should be relevant, reliable, and realistic, reflecting both the voice of the customer and the voice of the process. Additionally, you need to set baselines for your current state, representing the values of your metrics before any changes are implemented. These baselines will serve as a benchmark for comparing your pre- and post-improvement results, helping you quantify the impact of your efforts.

Collect and Analyze Data

With your metrics and baselines in place, the next step is to collect and analyze data consistently to monitor the progress and performance of your process improvements. A variety of tools and techniques are at your disposal for data collection and analysis. These include surveys, interviews, observations, checklists, as well as more advanced methods such as charts, graphs, histograms, control charts, Pareto charts, and root cause analysis. Data analysis will help you identify trends, patterns, anomalies, and opportunities for further enhancements.

Use Feedback Loops

Feedback loops are powerful mechanisms that enable you to receive and respond to input from your customers, stakeholders, and team members regarding your process improvements. These loops play a pivotal role in validating your assumptions, testing your solutions, evaluating your results, and adapting your actions accordingly. You can create feedback loops through methods like focus groups, customer reviews, surveys, audits, coaching, and mentoring. Feedback loops ensure that your improvement projects stay aligned with the evolving needs and expectations of your stakeholders.

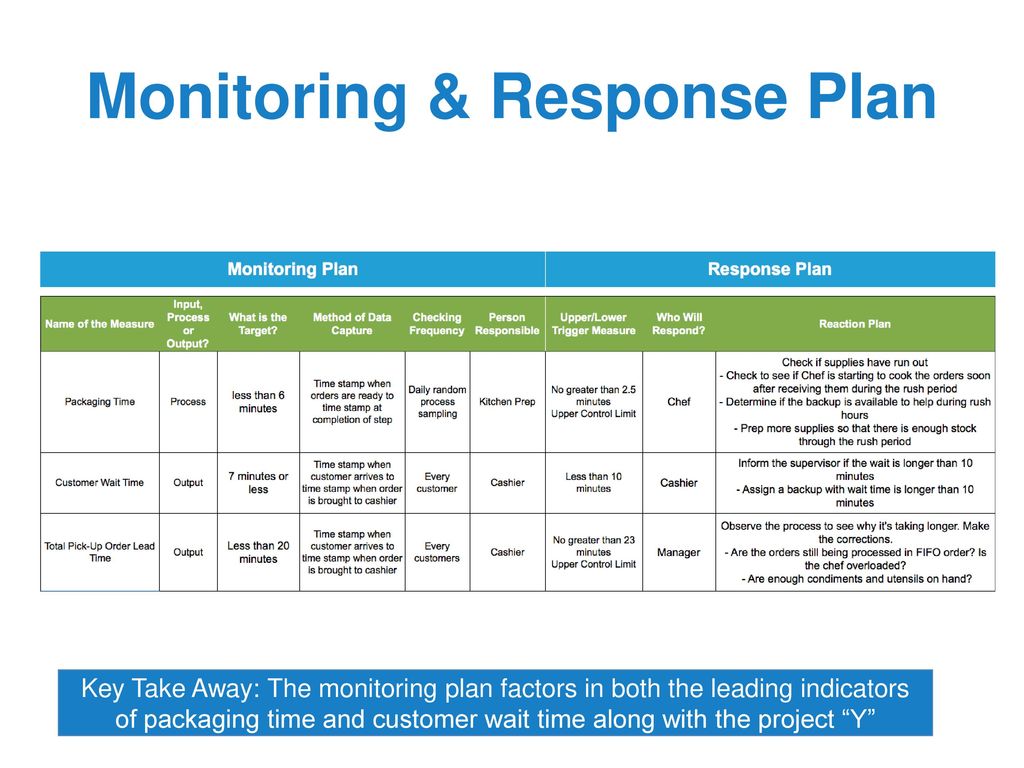

Implement Control Plans

Control plans are comprehensive documents that outline how to maintain and monitor the improved process while preventing it from reverting to its previous state. They specify the roles and responsibilities of process owners and operators, the methods and tools for control, the frequency and criteria for monitoring and evaluation, and the actions to be taken in the event of deviations. Control plans are invaluable for standardizing and documenting your process improvements, ensuring their sustainability and consistency over time.

Review and Report Results

The final step in the process of monitoring improvements is to review and report the results of your projects to your stakeholders and sponsors. Regular review and reporting, using the metrics and baselines defined at the outset, are essential for effectively communicating your achievements, celebrating your successes, and learning from your failures. Highlight the benefits and challenges of your process improvements and provide recommendations for future actions. This step in the process helps you maintain transparency and accountability throughout your Lean Six Sigma journey.Monitoring process improvements is a critical aspect of Lean Six Sigma, ensuring that the hard work and dedication put into improvement projects lead to tangible, sustained results. As you continue to fine-tune your Lean Six Sigma skills and enhance your understanding of efficient processes, remember to keep checking in, collecting data, and adapting to meet the ever-evolving needs of your stakeholders and customers. Your journey to achieving business efficiency and customer satisfaction through Lean Six Sigma continues!